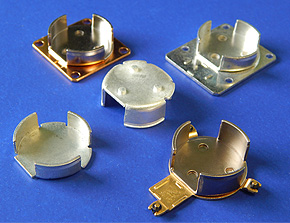

At Excel Tool & Die we pride ourselves on being a single source for metal parts solutions, employing a comprehensive set of capabilities added to superior customer service. We are recognized fabricators for the electronics industry, and the project highlighted here exemplifies our specialized abilities in that field. We were commissioned to produce a family of steel housings by an electronics customer, a project that we could streamline with our in-house tooling capabilities. A cost effective solution was devised by designing a universal progressive die, enabling the production of four variations of similar parts. .040″ thick steel in a 2″ wide coil was selected for the housings, manipulated to the specified configurations with a combination of stamping and specialized fabrication processes. The tightest tolerances of ±.003” were achieved. There were particularly challenging design aspects of the housings, including difficult forming requirements along with stamped grooves and extruded punch pin features. The finishing requirements for the parts were also demanding, requiring specialized plating for soldering applications which had to be closely monitored. Our dedication to detail was showcased here, producing housings with RoHS compliant tin over nickel, silver over copper, and gold over nickel finishes.

Production levels for the housings have reached 2,000,000 units per year, released via blanket order. The initial contract volumes with this customer were low, but over time, our consistent workmanship and high performing products motivated the customer to source volumes, which increased 10 fold, from Excel Tool & Die. We invite customers to leverage our six decades of experience to increase their quality, consistency, and bottom lines. To learn more about these steel housings, or for more information regarding our precision metal stamping capabilities and custom tooling expertise please see the table below or contact us directly.