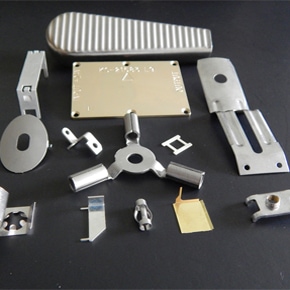

At Excel Tool & Die Co., our precision stamping services have an industry leading reputation for quality and reliability. Specializing in close tolerance thin gauge components, we can supply products in continuous strip or bulk form. Our talented and motivated team of tool and die professionals create compound, progressive, and forming dies with tremendous skill and proactively maintain them for use on a moment’s notice. We have the ability to create finely tuned geometric features through embossing, ribbing, extruding, punched countersinks, and shallow draws.

With high speed presses operating at 140 strokes/minute, we have the capacity to stamp parts with dimensions up to 18” x 12” from a wide variety of metals measuring from .002” to .125” thick. Our advanced manufacturing systems enable us to achieve tolerances as close as ±.005” with outstanding repeatability. All of our production, test, and inspection processes are managed according to our ISO 9001:2000 compliant quality program to ensure we meet all critical dimensional and performance specifications.

We are extremely agile and have the flexibility to rapidly respond to shifting customer priorities. Our extensive production resources allow us to manage large, ongoing orders through custom tailored Kanban systems that guarantee short lead times, stable pricing, and firm just-in-time delivery dates. We have extensive experience producing critical parts for the medical and electronics industries, as well as a solid background in the automotive, appliance, communications, and many other demanding markets.

To learn more about our precision stamping capabilities, please review the table below. Contact us at any time for a quote on your next order.